TZL30A XHZLC40 XHZLC60 Fire Self-rescue Respirator

Cat:Fire Escape Mask

The TZL30A XHZLC40 XHZLC60 Fire Escape Respirator is an advanced personal protective device designed to safeguard individuals during fire emergencies ...

See DetailsAir Supply Rate: The capacity of a breathing air compressor, quantified in cubic feet per minute (CFM) or liters per minute (LPM), defines its air delivery rate. A compressor with a higher capacity can deliver a larger volume of compressed air per minute, which is critical for applications requiring significant airflow. For instance, in industrial settings where multiple pneumatic tools or machinery are operated simultaneously, a high-capacity compressor ensures a consistent and ample air supply, preventing downtime and inefficiencies. In contrast, a compressor with lower capacity may struggle to meet the demands of high-volume applications, leading to potential disruptions and reduced productivity.

Pressure Levels: The capacity of a compressor affects its ability to generate and maintain the necessary pressure levels. High-capacity compressors are designed to sustain higher pressures over extended periods without significant fluctuations. This capability is vital in applications where pressure consistency is crucial, such as in spray painting or sandblasting, where variations in pressure can affect the quality of the finish or the effectiveness of the process. In safety-critical environments like firefighting or diving, maintaining stable pressure is essential for ensuring the safety and reliability of breathing apparatuses.

Operational Efficiency: Compressors with greater capacity are often engineered to handle more demanding operational conditions with greater efficiency. These compressors can manage higher workloads with less strain on the equipment, reducing the likelihood of mechanical failures and extending the overall lifespan of the unit. Efficient operation also means less frequent maintenance and repairs, translating to lower long-term costs and improved reliability. In contrast, compressors operating near their maximum capacity may experience higher wear rates and increased maintenance needs, potentially leading to higher operational costs and reduced service life.

Number of Users: In scenarios where multiple users require access to compressed air simultaneously, such as in large-scale industrial facilities or emergency response teams, the compressor's capacity is critical. A high-capacity compressor can provide sufficient air flow to support several users at once without compromising the pressure or flow rate. This ensures that each user receives an adequate supply of air, which is essential for maintaining operational efficiency and safety. Conversely, a compressor with insufficient capacity may lead to inadequate air supply, resulting in reduced performance and potential safety hazards.

Application Suitability: Different applications have varying air requirements, and the compressor’s capacity must align with these needs. For example, high-capacity compressors are indispensable in manufacturing processes that involve heavy-duty pneumatic tools, automation systems, or high-volume air applications. They are also suited for environments where continuous and reliable air supply is essential. On the other hand, applications with lower air demand, such as small-scale maintenance tasks or occasional use scenarios, can be effectively managed with a lower-capacity compressor, offering a more cost-effective solution.

Energy Consumption: The energy consumption of a compressor is directly related to its capacity. High-capacity compressors typically consume more power, which can significantly impact operating costs. It's crucial to evaluate the energy efficiency of the compressor to balance performance with cost-effectiveness. Modern compressors often feature energy-saving technologies and variable-speed drives that adjust the compressor’s output based on demand, helping to reduce energy consumption and operational costs. Selecting a compressor that offers both high performance and energy efficiency can result in long-term savings and a more sustainable operation.

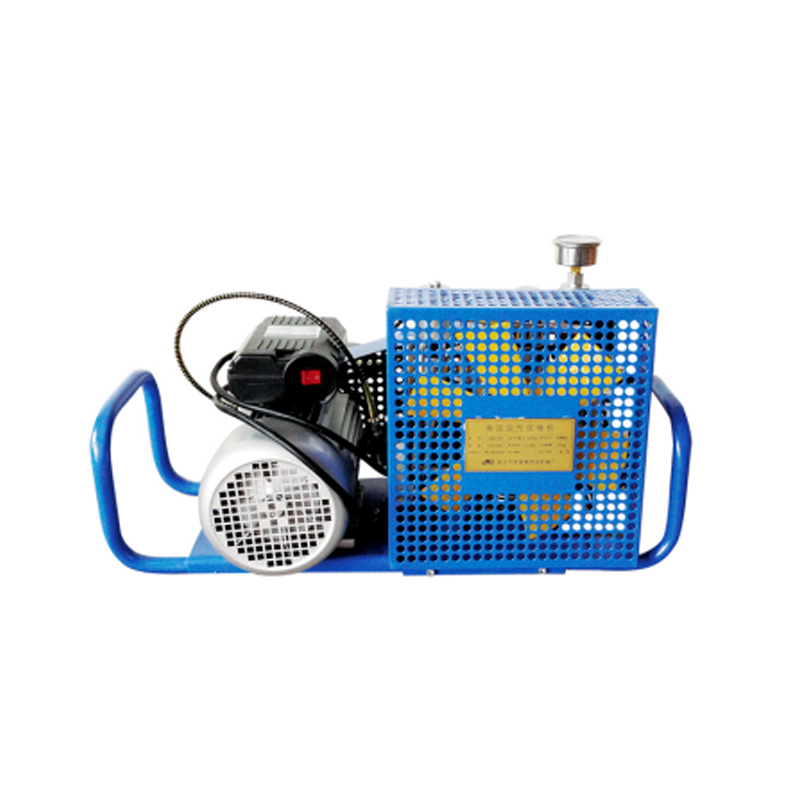

JGW-100 Breathing Air Compressor