TZL30A XHZLC40 XHZLC60 Fire Self-rescue Respirator

Cat:Fire Escape Mask

The TZL30A XHZLC40 XHZLC60 Fire Escape Respirator is an advanced personal protective device designed to safeguard individuals during fire emergencies ...

See DetailsNoise levels from a breathing air compressor can significantly impact the working environment, particularly in settings where concentration and communication are critical, such as in medical facilities, dive centers, or industrial workplaces. High noise levels can lead to several issues:

Hearing Damage: Prolonged exposure to high noise levels, especially those generated by industrial equipment like breathing air compressors, can result in hearing damage or loss over time. The risk is particularly significant in environments where the compressor operates continuously or for extended periods. To protect workers' hearing, it is essential to monitor noise levels and implement protective measures. Failure to address high noise levels can lead to increased incidences of noise-induced hearing loss (NIHL), which not only affects individual workers' health but also increases liability for employers.

Stress and Fatigue: Continuous exposure to loud noise can contribute to elevated stress levels and worker fatigue. The human body responds to loud noise as a stressor, which can lead to increased heart rate, blood pressure, and levels of stress hormones. Over time, this can result in chronic stress, decreased job satisfaction, and a decline in overall well-being. Fatigue from constant noise exposure can impair concentration, slow reaction times, and increase the likelihood of accidents. Thus, managing noise levels is not only a matter of comfort but also a critical factor in maintaining a healthy, productive workforce.

Options for Noise Reduction

Acoustic Enclosures: Acoustic enclosures are one of the most effective solutions for reducing noise levels from breathing air compressors. These enclosures are designed to encapsulate the compressor within a soundproofed barrier, significantly dampening the noise that escapes into the surrounding environment. Acoustic enclosures are typically constructed from materials with high sound absorption properties, such as specialized foam or dense, layered composites. They can be custom-built to fit the specific dimensions of the compressor and can include features such as ventilation systems to prevent overheating. By isolating the noise source, acoustic enclosures help maintain a quieter working environment while allowing the compressor to operate efficiently.

Vibration Isolation: Much of the noise generated by a breathing air compressor is due to vibrations that travel through the compressor’s structure and into the surrounding environment. Vibration isolation involves using specialized pads, mounts, or bases designed to absorb and dissipate these vibrations before they can propagate. These isolation systems are typically made from materials like rubber, cork, or neoprene, which are effective at dampening vibrational energy. By minimizing the transmission of vibrations, noise levels are reduced, and the overall operation of the compressor becomes quieter. Vibration isolation not only reduces noise but also prolongs the life of the equipment by reducing mechanical stress.

Silencers and Mufflers: Silencers and mufflers are devices installed on the intake and exhaust ports of a breathing air compressor to reduce the noise associated with air compression and discharge. These devices work by dissipating the sound energy produced during air intake and exhaust, often through a series of baffles or acoustic chambers that absorb and diffuse the noise. Silencers and mufflers are particularly effective in environments where the compressor must operate near workers or in noise-sensitive areas. They are available in various sizes and configurations to suit different compressor models and can be installed as part of a noise reduction strategy without significantly impacting the compressor’s performance.

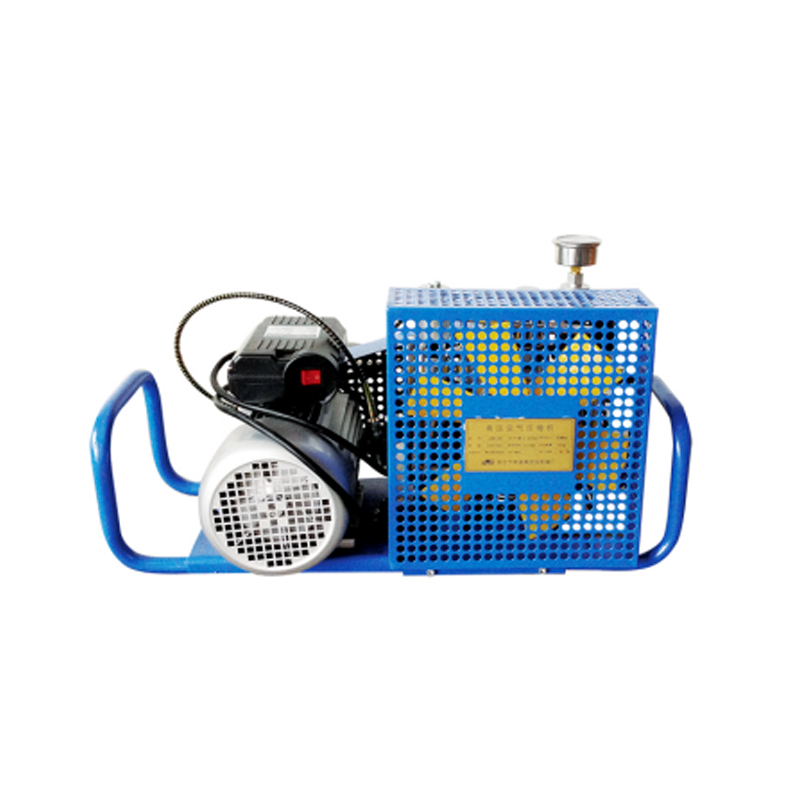

JGW-100 Breathing Air Compressor